Areas of application of braided flexible busbars

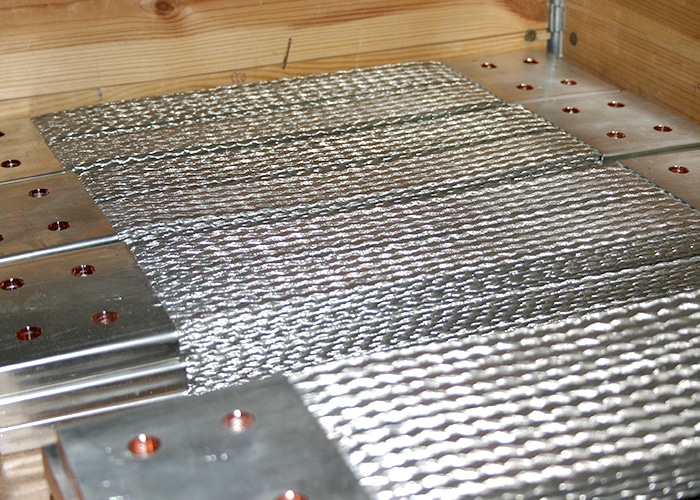

Braided flexible busbars (flat fabrics) are part of a highly flexible connection technology and are used, for example, as mobile elements in switchgear and device construction.

Braided flexible connectors enable the transmission of high currents between components that are subject to vibrations and compensate three-dimensional movements. In particular, round strands enable a high degree of flexibility in all directions of movement. Braided flexible connectors (flat fabrics) are part of a highly flexible connection technology and are used, for example, as mobile elements in switchgear and device construction.

The machine produced flat and round braids consist of thin individual wires with solid connections made of mechanically pressed sleeves or out of cable lugs.

EMS produces tailor-made connection technology, but also offers braided flexible busbars in various dimensions.

- High power transmission with relatively small and very flexible components

- High quality and flexibility

- Enables displacements in all levels

- Absorbs vibrations and expansions

Conductor material of braided flexible busbars

- Cu-ETP1 red

- Cu-ETP1 tinned

- Aluminum

- Stainless steel

- Single wire thickness 0.07–0.3 mm

EMS has a high level of experience in manufacturing technical and highly developed connections made of different materials:

- Pressure welded connections are produced directly without a sleeve using the pressure welding process. To avoid oxidation, structural changes and tarnishing, the pressure welding process is performed under water or protective gas.

- Pressed pipe connectionsare made of copper, aluminum or stainless steel. The pressing takes place on all sides under high pressure in a calibrating device with which a material filling level of over 95% is achieved. Tapes of this type can be manufactured by EMS in different metals, in all shapes, sections, ranges, etc. on request.

- Connections with standardized cable lugs are pressed onto round stranded wire.

More connections on Inquiry!

Assembly & Processing of braided flexible busbars

Technical details

Production based on DIN 46276 !

| Typenbez. / Type | Breite / Width [mm] | Gewicht Stk. / Weight pcs. [kg] |

|---|---|---|

| LICU 120/40/60/220 | 40 | 0,42 |

| LICU 240/40/60/220 | 40 | 0,67 |

| LICU 360/50/60/250 | 50 | 1,08 |

| LICU 480/50/60/250 | 50 | 1,40 |

| LICU 600/60/80/310 | 60 | 2,08 |

| LICU 720/80/80/310 | 80 | 2,50 |

| LICU 960/100/100/350 | 100 | 3,67 |

Possible EMS confections

- MIG & TIG welding

- Pressure welding

- Explosive cladding

- Electron beam welding

- Aluminothermic welding

- Brazing

- Individual lengths on request

- Personalization

- Packaging according to customer specifications