Application area Ultraflexx® highly flexible busbars

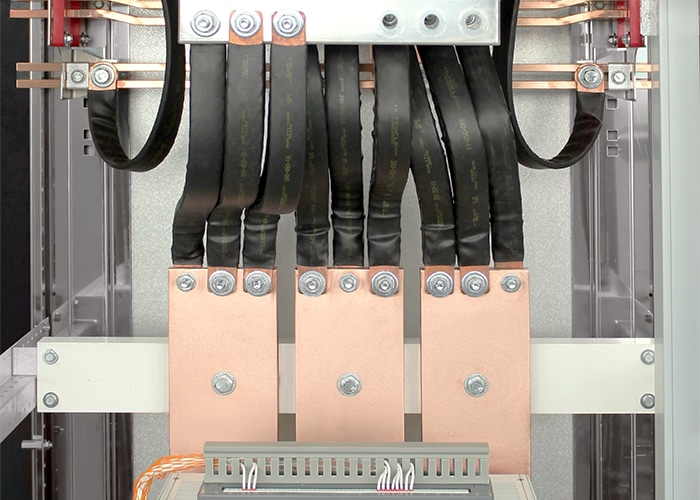

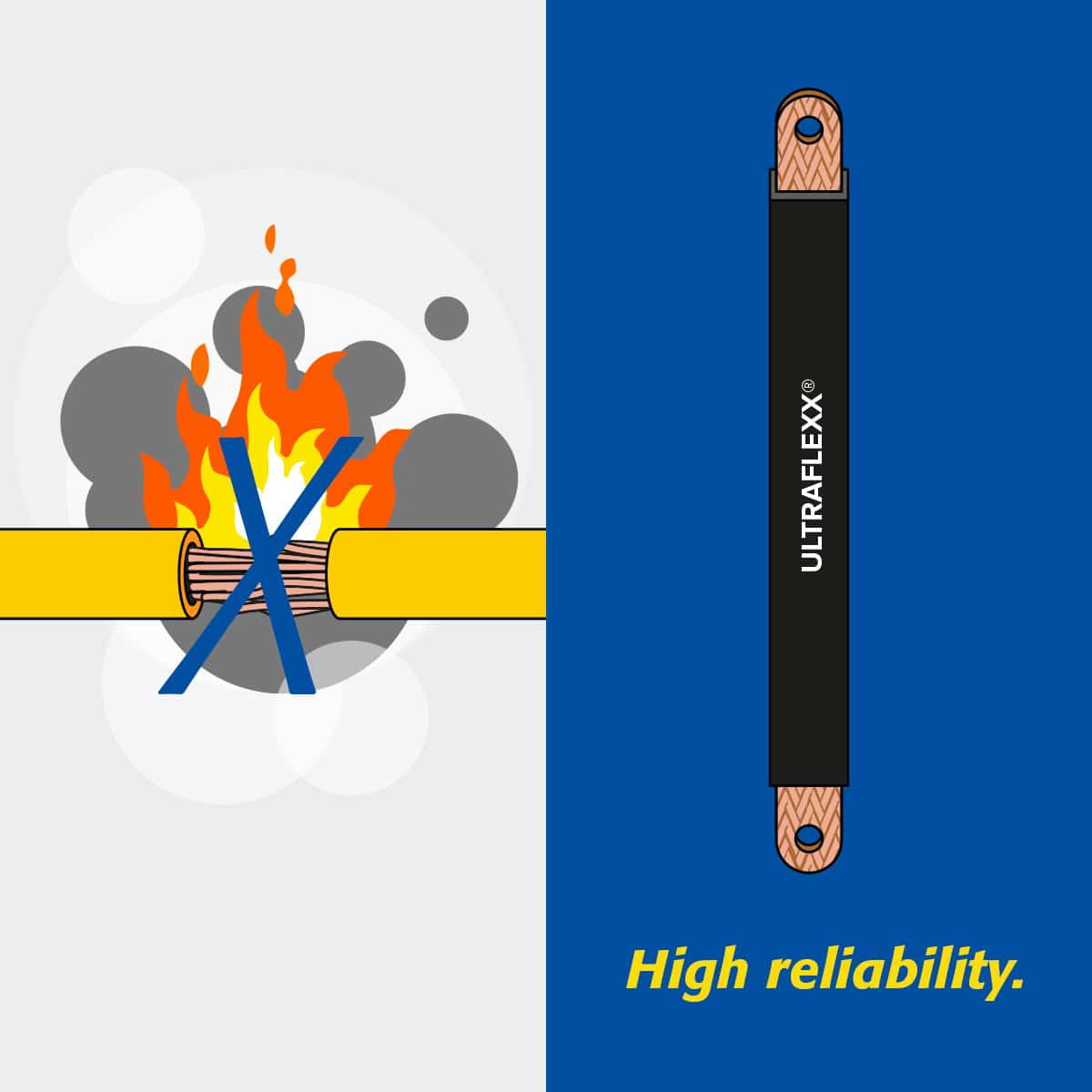

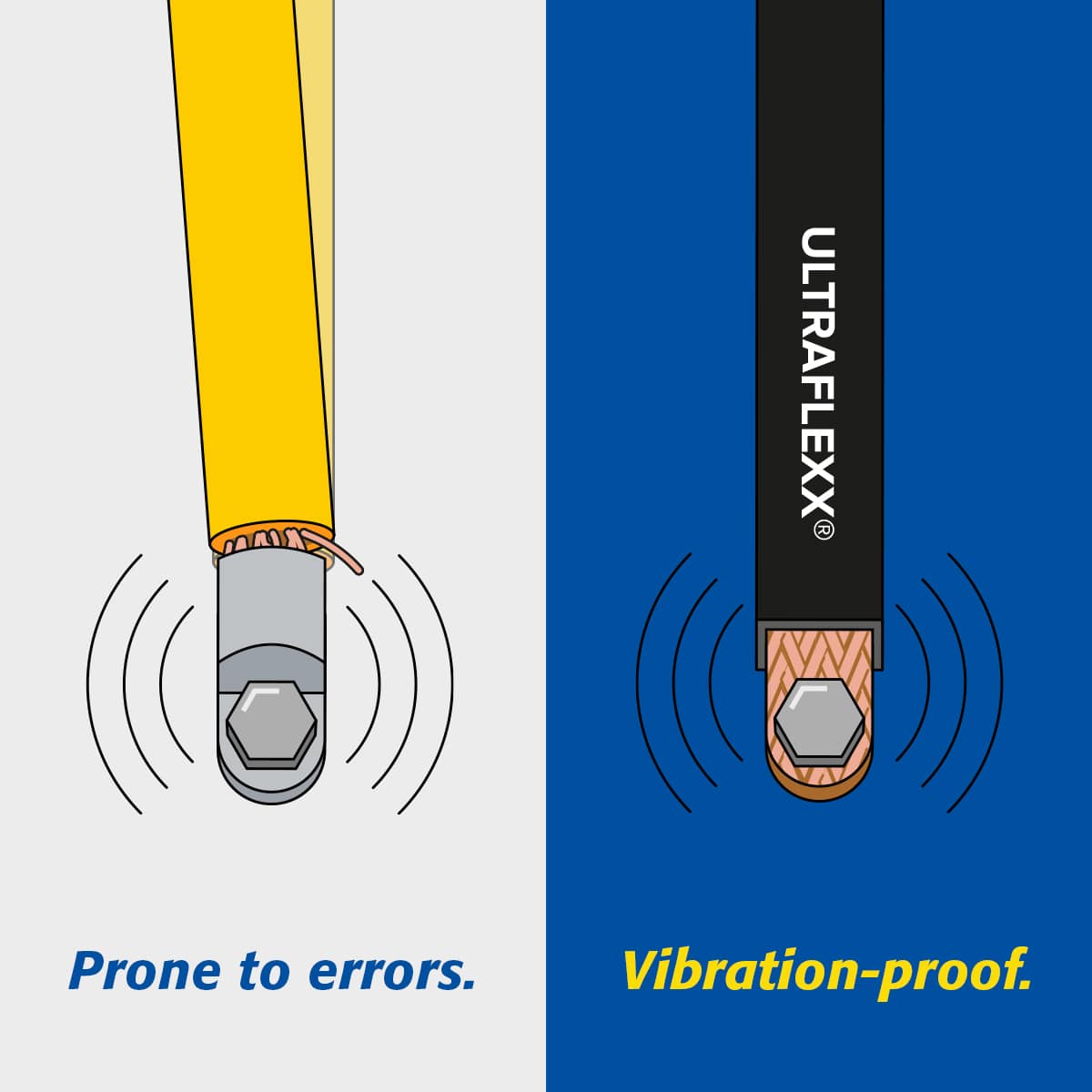

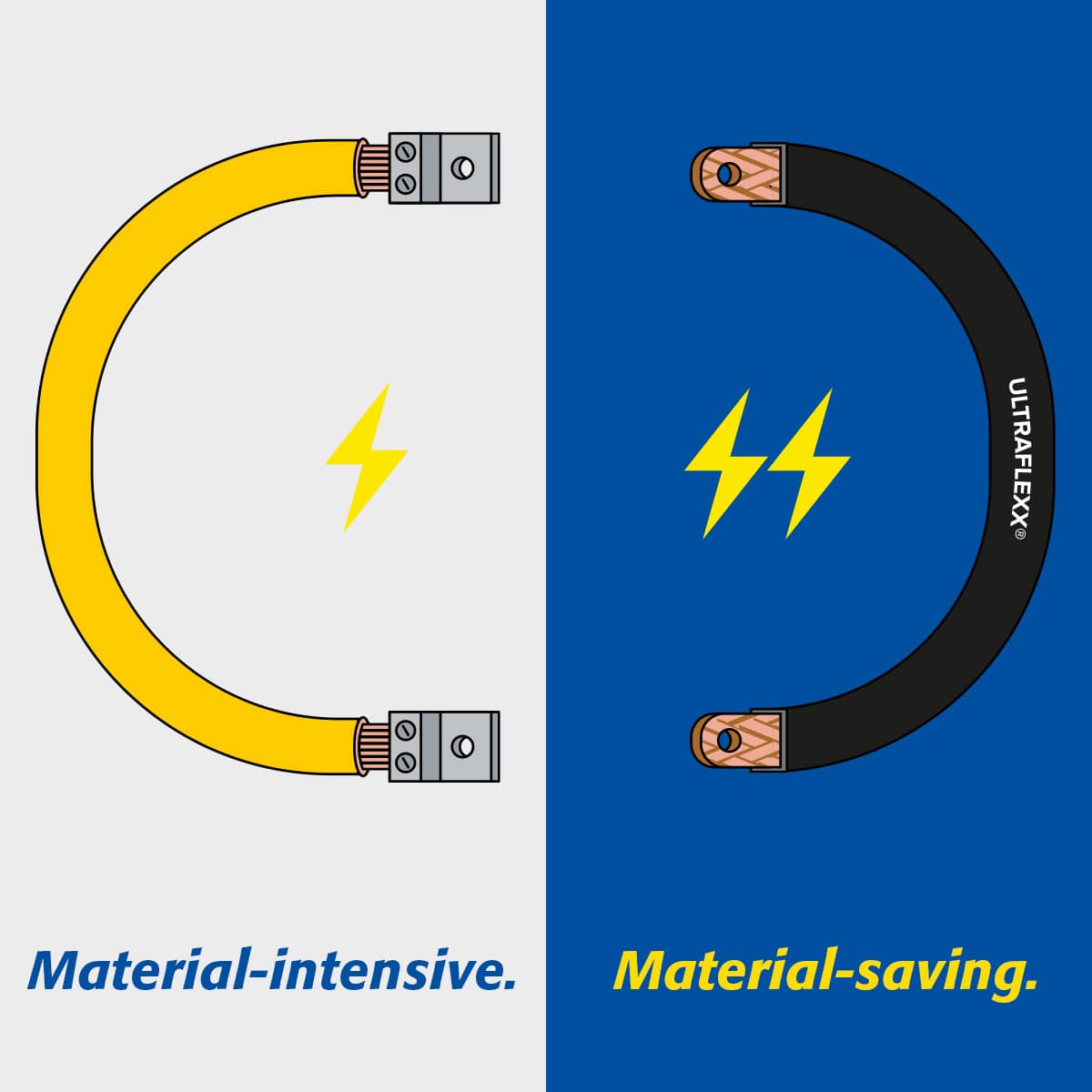

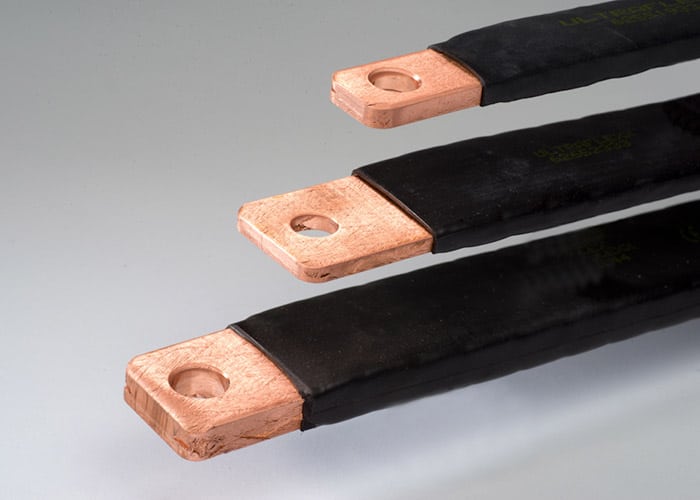

Ultraflexx® highly flexible busbars are flexible connectors made of flat copper mesh and reliably absorb vibrations and switching surges.

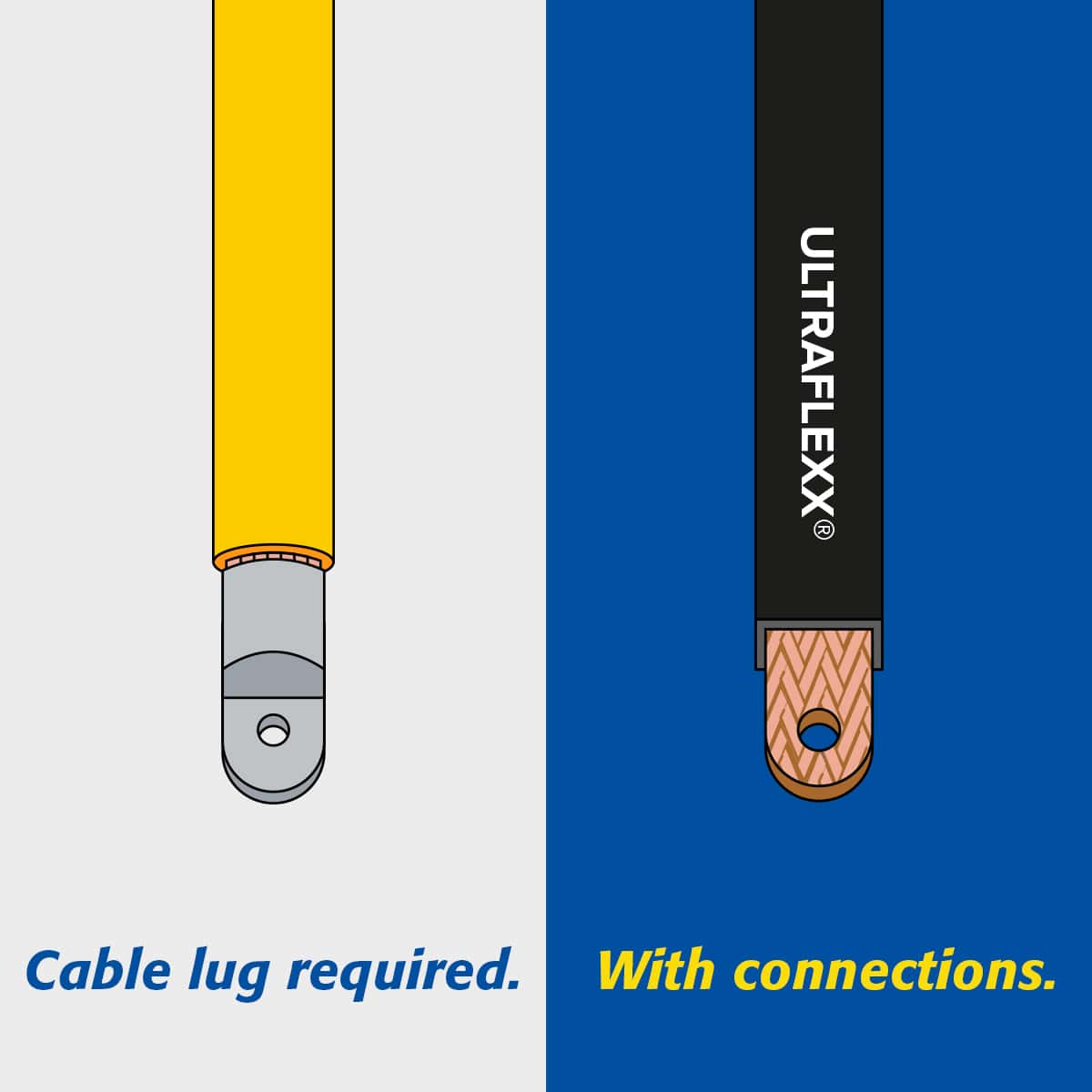

The press-welded connections are (contrary to the generally available press technology) press-welded over the entire connection cross-section and can be processed like a solid end piece.

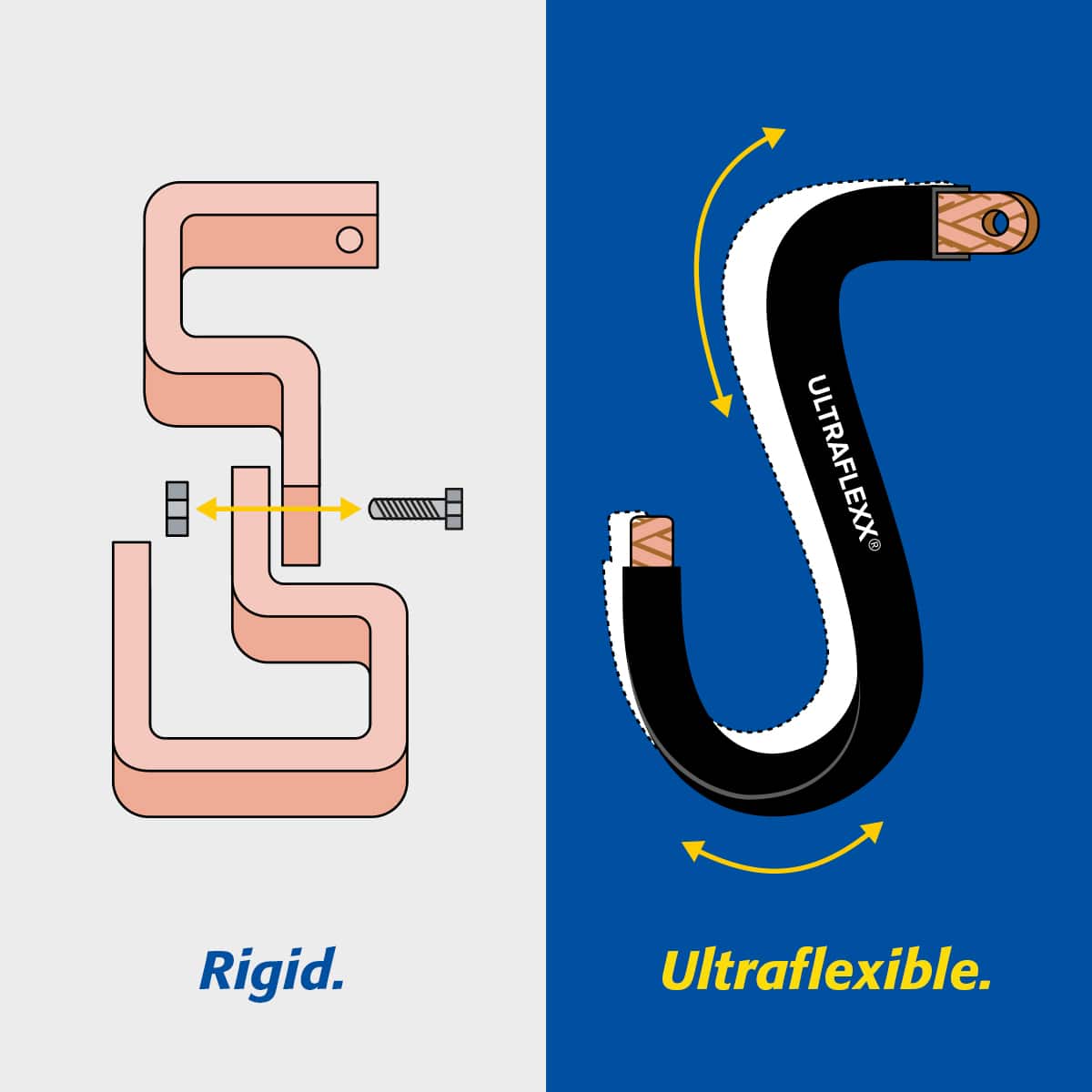

Ultraflexx® highly flexible busbars are robustly insulated and are ideal for flexible use of space and are the best alternative to pre-assembled cables. Thanks to our different cross-sections, Ultraflexx® highly flexible busbars can be adapted to a wide range of equipment and used as connectors between various control cabinet modules and units.

- Low heating in the event of a short circuit

- Best mechanical long-term behavior

- High operational reliability

- Excellent contact transition

Ultraflexx® conductor material

- Highly flexible flat mesh made of Cu-ETP1 with excellent

- Conductivity and press-welded connections

- Electrical conductivity 58 MS/m

- Single wire diameter 0.15 mm

- Cu-ETP1 bare

- Cross-sections from 25 to 240 mm²

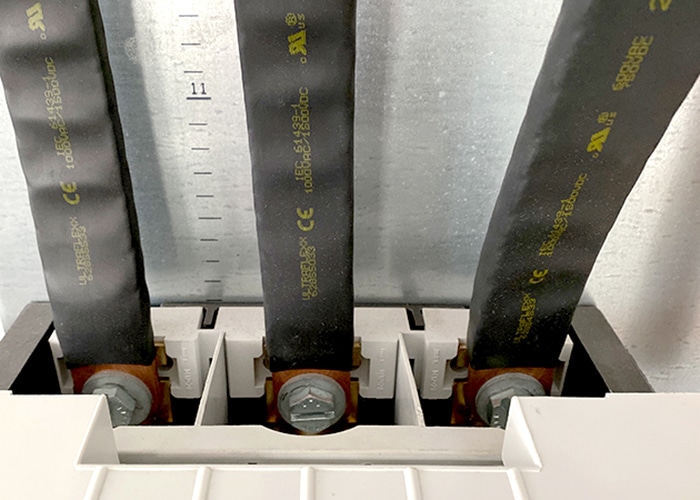

- Length is defined as hole center distance

- Lengths from 150 to 1000 mm, in 50 mm increments

Connections with press-welded connection ends

- The connection ends can be machined like a solid end piece.

- They are vibration-resistant and allow minimal contact resistance to pass through.

- Lower power loss and smaller voltage drop.

- No corrosion and therefore no deterioration of the connection resistances over time

The bending radii of our Ultraflexx® highly flexible busbars were determined on the assumption that the connections run parallel to each other (regular and flat edge). However, they are only approximate values:

Ultraflexx® with a cross-section of 25 m²

→ ULFX 25 m² = approx. 6 cm

→ ULFX 25 m² flat = approx. 6 cm

Ultraflexx® with a cross-section of 50 m²

→ ULFX 50 m² = approx. 6 cm.

→ ULFX 50 m² flat = approx. 6 cm.

Ultraflexx® with a cross-section of 100 m²

→ ULFX 100 m² = approx. 7 cm.

→ ULFX 100 m² flat = approx. 7 cm

Ultraflexx® with a cross-section of 120 m²

→ ULFX 120 m² = approx. 8 cm

→ ULFX 120 m² flat = approx. 8 cm

Ultraflexx® with cross-section 240 m²

→ ULFX 240 m² = approx. 9 cm

→ ULFX 240 m² flat = approx. 9 cm

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationInsulation Ultraflexx®

Ultraflexx® highly flexible busbars are robustly insulated to withstand high operating voltages:

- Halogen-free polyolefin hose, black

- Wall thickness 0.8 ±0.3 mm

- Operating temperatures -55° C to +125° C

- Flame retardant according to UL 224 – VW 1

- Operating voltage max. 1000 VAC – 1500 VDC

- Dielectric strength 20kV/mm

Assembly & processing Ultraflexx®

Technical details & current carrying capacity

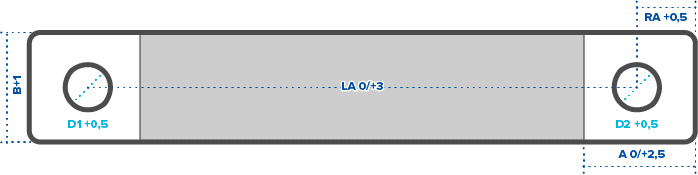

Ultraflexx type designation:

ULFX [cross-section mm²] –

[LA = length of hole spacing] –

[D1 / D2 = hole diameter]

Lengths [LA] from 150-1000 mm in 50 mm increments. The length is defined as the hole center distance.

For Ultraflexx® current carrying capacity is determined according to the following table in accordance with IEC or UL standard.

Individual diameters D1/D2 at any time on request!

| Typenbez. / Type | Querschnitt / Cross section [mm²] | LA Länge / Length [mm] | D1/D2 Durchmesser / Diameter [mm] | B Breite / Width [mm] (± 1) | A Anschlusslänge / Length connection [mm] | RA Abstand / Distance [mm] | Gewicht / Weight [kg/m] | Dicke Innen : Anschluss / Thickness inside : connection [mm] | Leitertemp. /Conductor temp.[A]* 65 °C | Leitertemp./ Conductor temp. [A]* 85 °C | Leitertemp./ Conductor temp. [A]* 105 °C |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ULFX 25-LA-D1/D2 | 25 | 150-1000 | 8,5/10,5 | 20 | 35 | 9 | 0,25 | ca. 1,5 : 1,4 | 159 | 210 | 250 |

| ULFX 50-LA-D1/D2 | 50 | 150-1000 | 8,5/10,5 | 20 | 35 | 9 | 0,51 | ca. 3,9 : 2,8 | 236 | 311 | 370 |

| ULFX 100-LA-D1/D2 | 100 | 150-1000 | 10,5/10,5 | 20 | 35 | 9 | 1,02 | ca. 8,0 : 5,9 | 350 | 462 | 550 |

| ULFX 120-LA-D1/D2 | 120 | 150-1000 | 10,5/10,5 | 32 | 35 | 12 | 1,22 | ca. 4,6 : 4,4 | 382 | 504 | 600 |

| ULFX 240-LA-D1/D2 | 240 | 150-1000 | 10,5/10,5 | 32 | 35 | 12 | 2,44 | ca. 9,1 : 8,9 | 688 | 908 | 1080 |

*Current load values: Ambient temperature 35 °C, alternating current AC. Please use a multiplication factor of 1.72 when using 2 Ultraflexx® and a multiplication factor of 2.25 when using 3 Ultraflexx® in parallel.

Possible SPS configuration

- Individual lengths on request

- Individual insulation on request

- Personalizations

- Packaging according to customer specifications