Areas of application for Isoflexx® laminated busbars

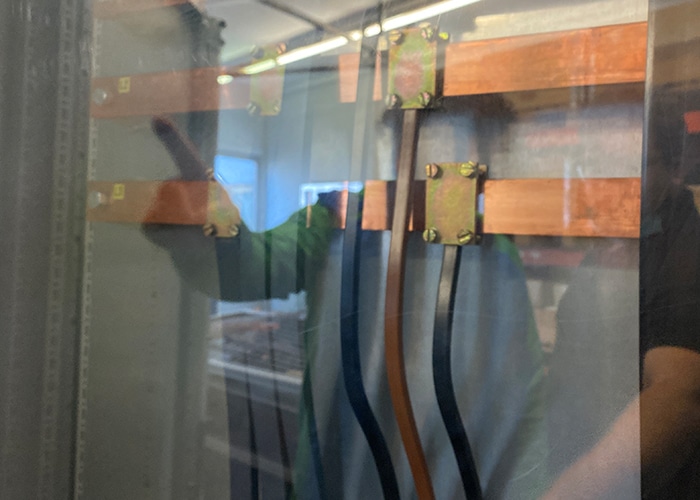

Isoflexx® laminated busbars made of copper can be used for all electrical connections in control cabinets and in low-voltage installations.

Whether as a movable component within solid busbar systems, for connection to generators, transformers, switchgear and switching devices, as a supply line to machine switches, and immersion baths or as a riser in switchgear – Isoflexx® busbars are innovative and cost-effective connections.

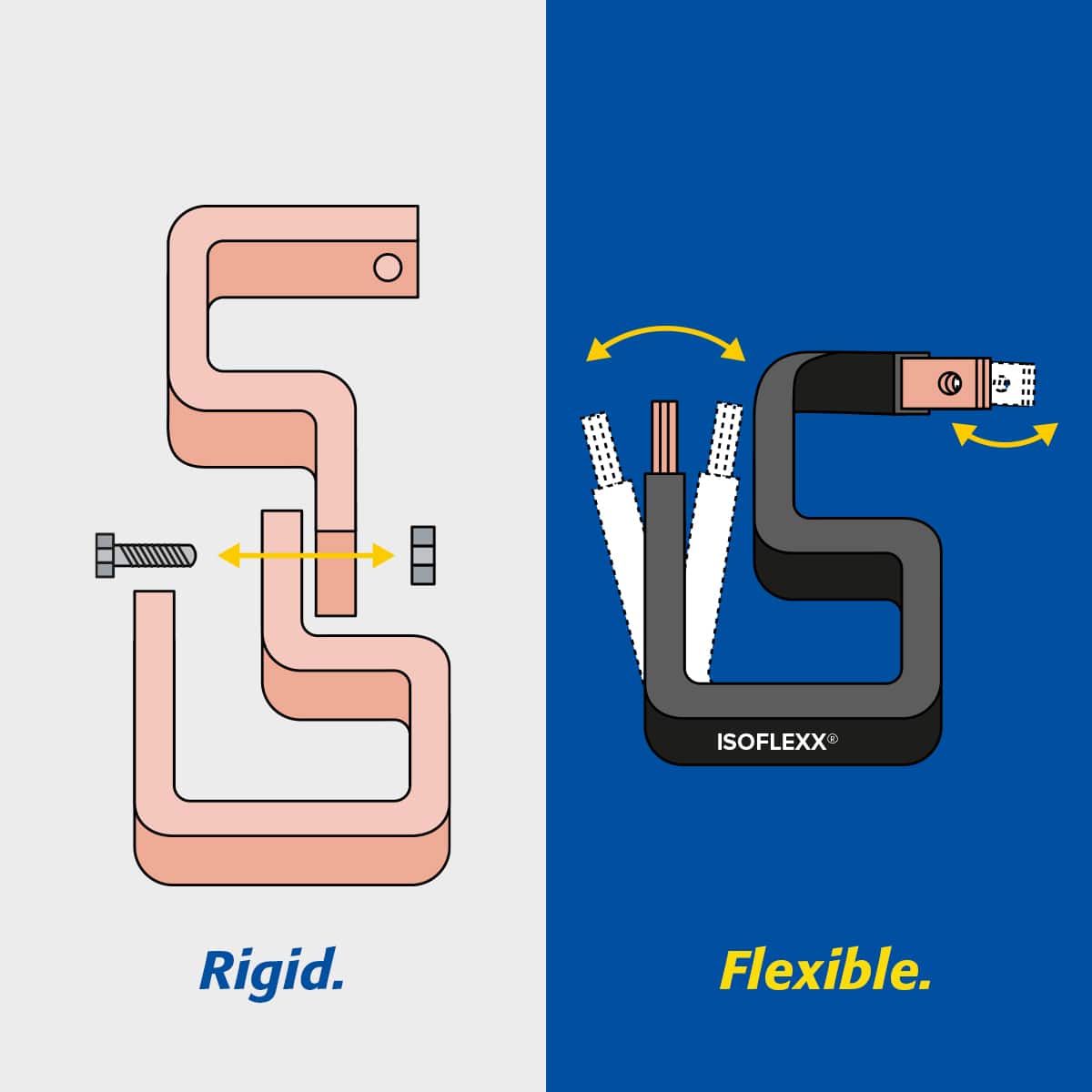

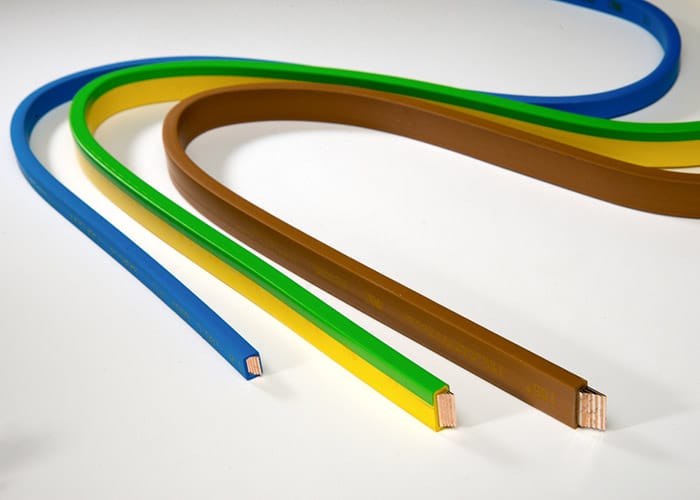

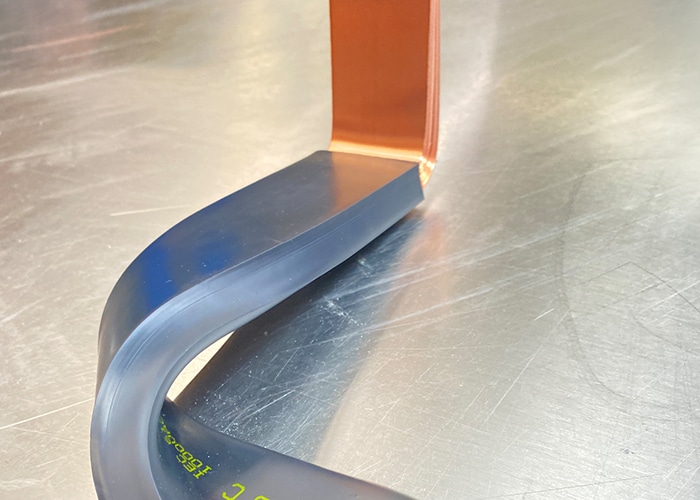

The loose lamellae in the insulation allow for easy bending or twisting and thus offer excellent flexibility when installing the busbars. Isoflexx® copper busbars are also suitable for drilling or punching.

- Very good flexibility

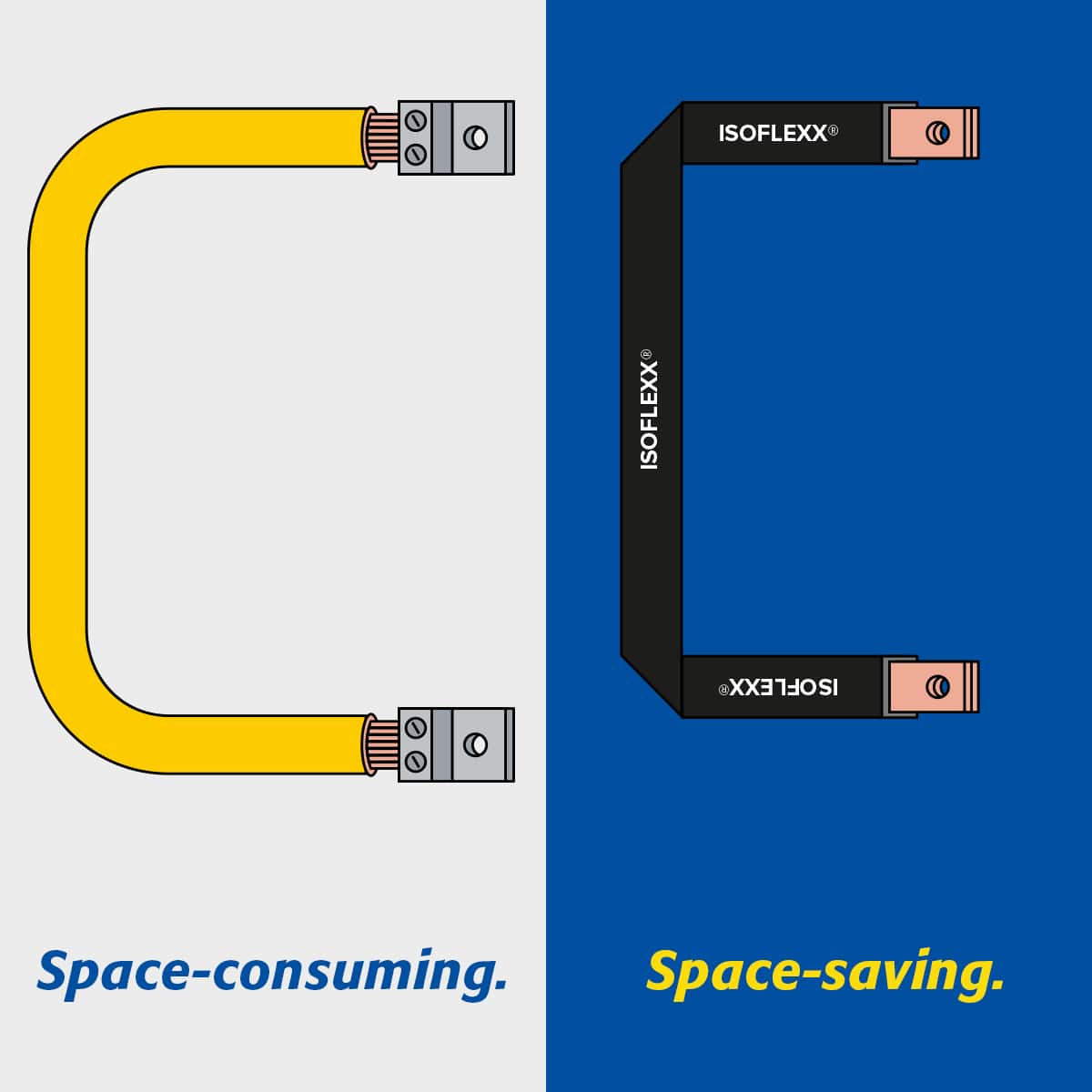

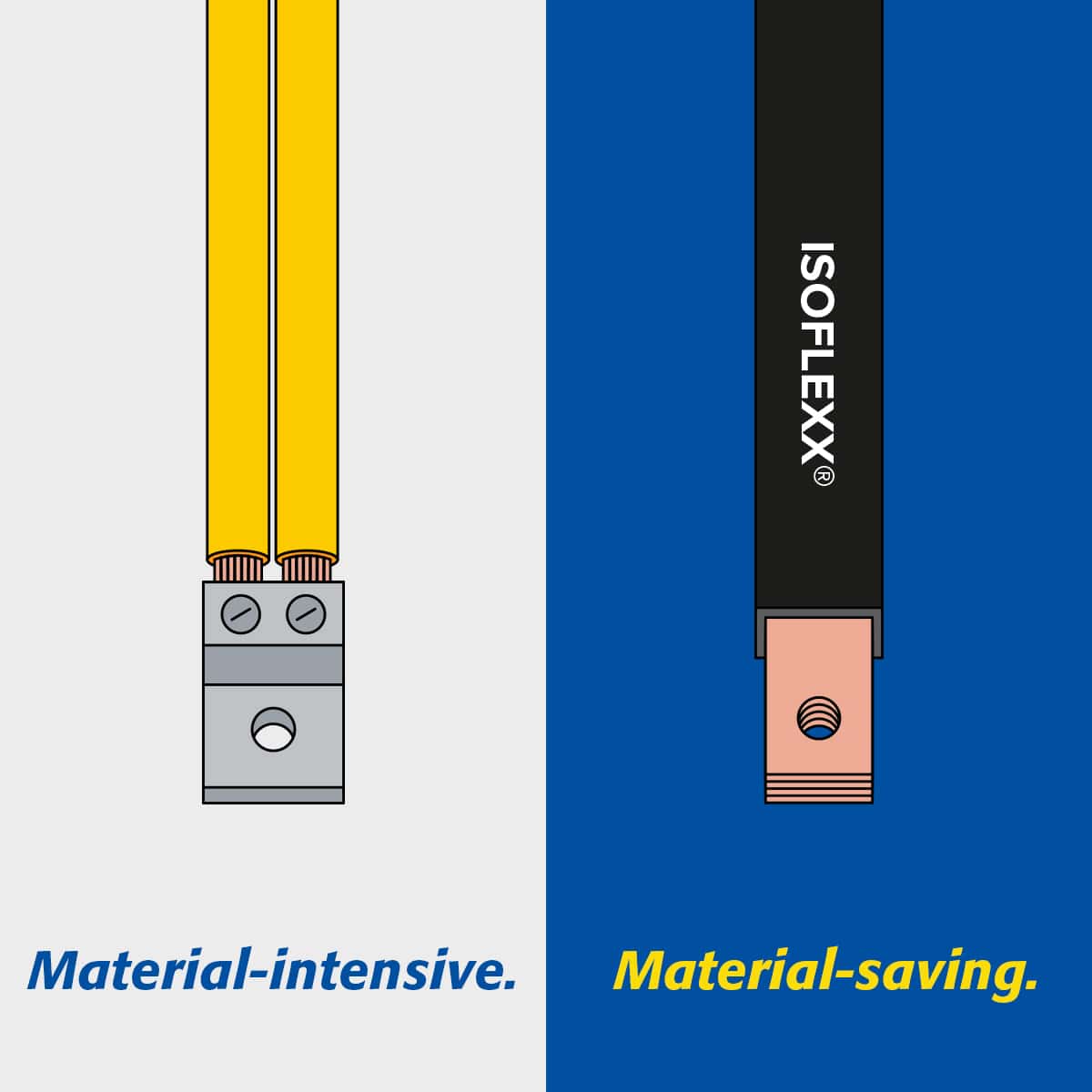

- Material & space saving

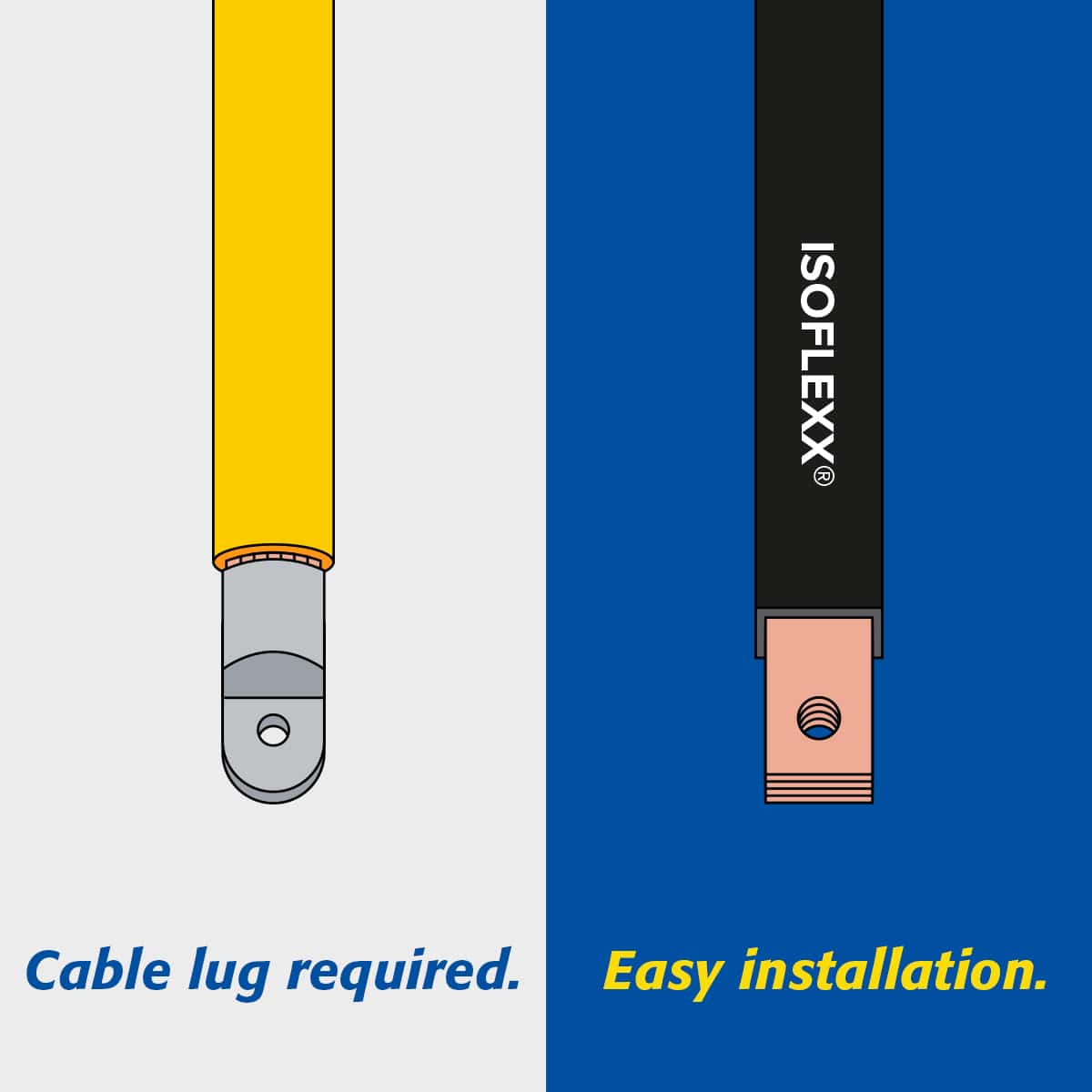

- Self-assembly

- High inherent strength

- UL approval

With the same load capacity

the conductor cross-section of

Isoflexx® compared to cables

up to 40 % smaller than cables

and thus allows for smaller

bending radii.

The flexibility allows the

compensation of construction

tolerances during installation

and the assembly time is

drastically reduced.

The smaller conductor cross-section

with Isoflexx® compared to cables

with the same current carrying

capacity reduces material consumption.

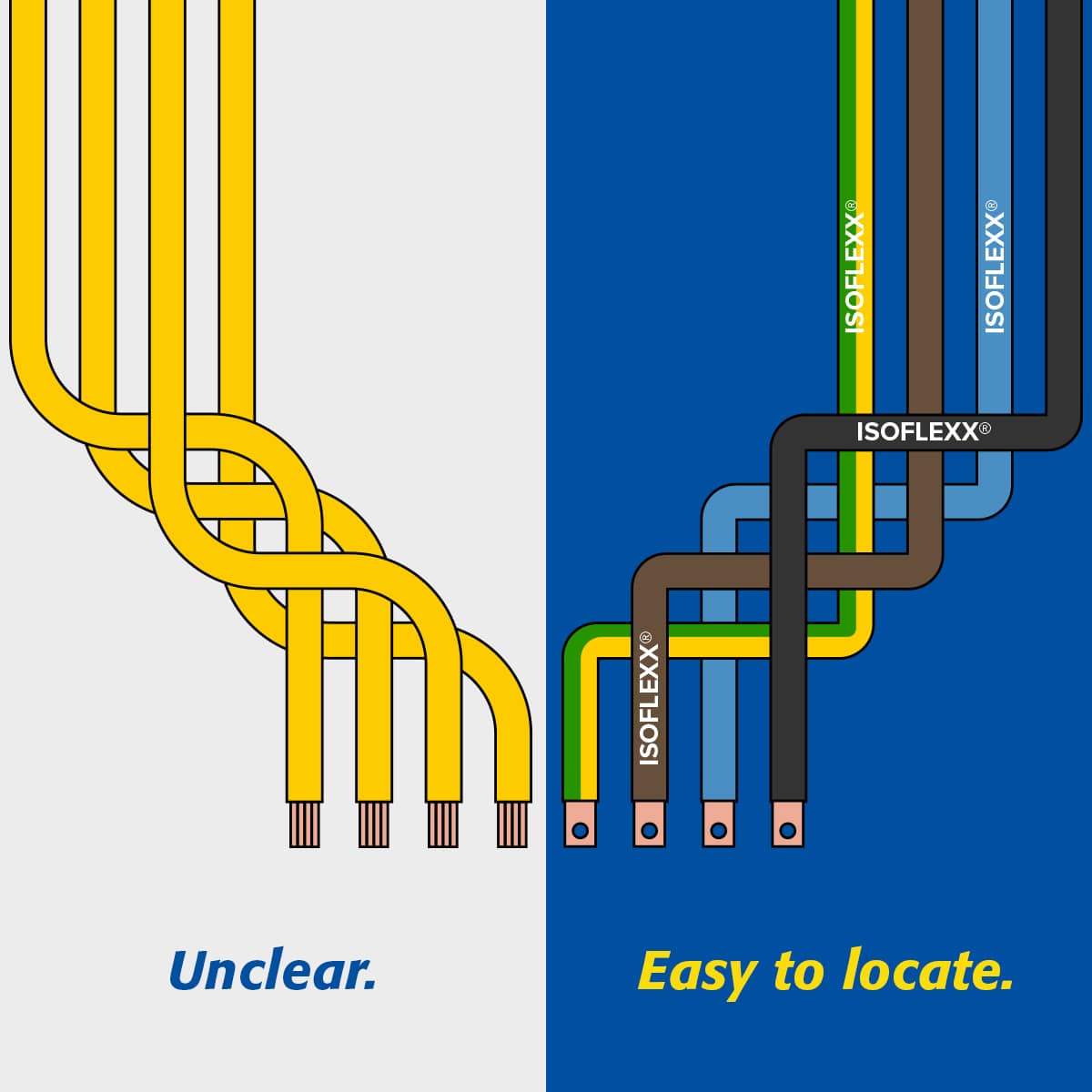

Choose between our standard

colours or personalise your

Isoflexx® and your control

cabinet systems gain in clarity

and safety.

Isoflexx® has reinforced

edges, uniform insulation

and are extremely heat

resistant. The dielectric

strength is tested.

Conductor material Iaminated busbars

- Cross-sections from 21.6 to 1200 mm²

- Standard length 2000 mm

- Lengths from 250 to 3000 mm on request

- Copper lamellae made of highly conductive Cu-ETP

- Tensile strength 200 MPa [R200]

- Electrical conductivity 58 MS/m

- Isoflexx® from 0.5 mm - 1.0 mm lamella thickness

- Cu-ETP blank

- Cu-ETP tinned (corrosion resistant)

Insulation variants of Isoflexx®

Our Isoflexx® Classic and Isoflexx® Premium (105-190 °C) allow higher temperatures than PVC or XLPE cables (70-90 °C). This means that a significantly higher current-carrying capacity can be achieved.

Isoflexx® insulation is resistant and has reinforced edges to withstand high operating voltages. The homogeneous, stress-free insulation prevents cracking at edges. Isoflexx® busbar insulation is available in various colours and complies with the RoHS directive.

| Product | Isoflexx® Classic | Isoflexx® Premium | Isoflexx® Rail |

|---|---|---|---|

| Colors insulation | Black, Blue, Green+Yellow | Grey | Black |

| Thickness [mm] | ≥ 1 | ≥ 2 | ≥ 1,5 |

| Dielectric strength | 20 kV/mm | 16 kV/mm | 21 kV/mm |

| Elongation | 370 % | 180 % | 550 % |

| Operating temperature | -40 °C / +105 °C | -40 °C / +190 °C | -40 °C / +105 °C |

| Operating voltage | 1000 VAC/1500 VDC (UL 600 VAC/750 VDC) | 1000 VAC/1500 VDC (UL 600 VAC/750 VDC) | 1000 VAC/1500 VDC |

| Flammability | UL 94 V0 | UL 94 V0 | UL 94 V0 |

| Glow wire test | 960°C | 960°C | 960°C |

| Material | Special PVC, Self-extinguishing, Migration resistant, Compatible with various construction materials | Silicone, Halogen free, Self-extinguishing | Thermoplastic elastomer (TPE), Halogen free, Insulation fulfills flame protection requirements for railroad applications |

| Approvals | UL 758, UL 508 | UL 508 | UL 94 V-0 (1.5 mm), DIN EN 45545-2 R22 HL2, DIN EN 45545-2 R23 HL3 |

Isoflexx® Classic

The special PVC insulation of Isoflexx® Classic is naturally self-extinguishing and is often used in industrial applications.

The plasticiser is migration resistant and compatible with construction materials such as polycarbonate and polymethyl methacrylate.

Approvals

UL 758, UL 508

Standards

RoHS, CE, REACH, IEC 61439-1

Isoflexx® Premium

The halogen-free silicone insulation of Isoflexx® Premium is self-extinguishing, produces only a very small amount of toxic smoke in case of fire and is therefore often used in public buildings.

The insulation tube is a homogeneous profile which is pulled over the conductor material.

Approvals

UL 508

Standards

RoHS, CE, REACH, IEC 61439-1

Isoflexx® Rail

Isoflexx® Rail’s halogen-free TPE insulation generates only a very small amount of toxic smoke in the event of fire and can therefore also be used in public facilities.

Isoflexx® Rail insulation also fulfills the flame protection requirements for rail applications – for greater safety for people and railroads.

Approvals

UL 94 V-0 (1,5 mm), DIN EN 45545-2 R22 HL2 (insulation), DIN EN 45545-2 R23 HL3 (insulation)

Standards

RoHS, CE, REACH, IEC 61439-1

Assembly & processing of Isoflexx®

Assembly & processing of laminated busbars

For Isoflexx® laminated busbars, the current carrying capacity applies according to the following table determined according to IEC or UL standard:

| Typenbez. / Type | Querschnitt / Cross section [mm²] | Anzahl Lamellen / Number lamellas | Breite Lamellen / Width lamellas [mm] | Dicke Lamellen / Thickness lamellas [mm] | Farbe Isolierung / color insulation | Strombelastung/ Current rating [A]* 65°C | Strombelastung / Current rating [A]* 85°C | Strombelastung / Current rating [A]* 105°C |

|---|---|---|---|---|---|---|---|---|

| IFX-C- 2 x 32 x 1 | 64 | 2 | 32 | 1 | Auf Anfrage / On request | 290 | 384 | 456 |

| IFX-C- 2 x 24 x 1 | 48 | 2 | 24 | 1 | Auf Anfrage / On request | 242 | 320 | 380 |

| IFX-C- 2 x 20 x 1 | 40 | 2 | 20 | 1 | Auf Anfrage / On request | 208 | 275 | 326 |

| IFX-C- 3 x 9 x 0,8 | 21,6 | 3 | 9 | 0,8 | 🟡+🟢, 🔵, ⚫️ | 121 | 160 | 190 |

| IFX-C- 3 x 32 x 1 | 96 | 3 | 32 | 1 | Auf Anfrage / On request | 361 | 477 | 567 |

| IFX-C- 3 x 24 x 1 | 72 | 3 | 24 | 1 | Auf Anfrage / On request | 303 | 400 | 475 |

| IFX-C- 3 x 20 x 1 | 60 | 3 | 20 | 1 | Auf Anfrage / On request | 261 | 345 | 410 |

| IFX-C- 4 x 32 x 1 | 128 | 4 | 32 | 1 | Auf Anfrage / On request | 421 | 556 | 661 |

| IFX-C- 4 x 24 x 1 | 96 | 4 | 24 | 1 | Auf Anfrage / On request | 348 | 460 | 546 |

| IFX-C- 4 x 20 x 1 | 80 | 4 | 20 | 1 | Auf Anfrage / On request | 303 | 400 | 475 |

| IFX-C- 4 x 15,5 x 0,8 | 49,6 | 4 | 15,5 | 0,8 | 🟡+🟢, 🔵, ⚫️ | 227 | 300 | 356 |

| IFX-C- 5 x 80 x 1 | 400 | 5 | 80 | 1 | Auf Anfrage / On request | 1.022 | 1.350 | 1.605 |

| IFX-C- 5 x 63 x 1 | 315 | 5 | 63 | 1 | Auf Anfrage / On request | 832 | 1.099 | 1.306 |

| IFX-C- 5 x 50 x 1 | 250 | 5 | 50 | 1 | Auf Anfrage / On request | 702 | 927 | 1.102 |

| IFX-C- 5 x 40 x 1 | 200 | 5 | 40 | 1 | Auf Anfrage / On request | 577 | 762 | 906 |

| IFX-C- 5 x 32 x 1 | 160 | 5 | 32 | 1 | ⚫️ | 480 | 634 | 753 |

| IFX-C- 5 x 24 x 1 | 120 | 5 | 24 | 1 | ⚫️ | 405 | 535 | 636 |

| IFX-C- 5 x 20 x 1 | 100 | 5 | 20 | 1 | Auf Anfrage / On request | 321 | 424 | 504 |

| IFX-C- 5 x 100 x 1 | 500 | 5 | 100 | 1 | Auf Anfrage / On request | 1.215 | 1.604 | 1.907 |

| IFX-C- 6 x 9 x 0,8 | 43,2 | 6 | 9 | 0,8 | 🟡+🟢, 🔵, ⚫️ | 189 | 250 | 297 |

| IFX-C- 6 x 80 x 1 | 480 | 6 | 80 | 1 | Auf Anfrage / On request | 1.105 | 1.460 | 1.735 |

| IFX-C- 6 x 63 x 1 | 378 | 6 | 63 | 1 | Auf Anfrage / On request | 949 | 1.253 | 1.489 |

| IFX-C- 6 x 50 x 1 | 300 | 6 | 50 | 1 | Auf Anfrage / On request | 772 | 1.020 | 1.212 |

| IFX-C- 6 x 40 x 1 | 240 | 6 | 40 | 1 | Auf Anfrage / On request | 632 | 835 | 992 |

| IFX-C- 6 x 32 x 1 | 192 | 6 | 32 | 1 | Auf Anfrage / On request | 530 | 700 | 832 |

| IFX-C- 6 x 24 x 1 | 144 | 6 | 24 | 1 | Auf Anfrage / On request | 439 | 580 | 689 |

| IFX-C- 6 x 20 x 1 | 120 | 6 | 20 | 1 | Auf Anfrage / On request | 357 | 472 | 561 |

| IFX-C- 6 x 15,5 x 0,8 | 74,4 | 6 | 15,5 | 0,8 | 🟡+🟢, 🔵, ⚫️ | 287 | 380 | 451 |

| IFX-C- 6 x 13 x 0,5 | 39 | 6 | 13 | 0,5 | 🔵, ⚫️ | 181 | 240 | 285 |

| IFX-C- 6 x 100 x 1 | 600 | 6 | 100 | 1 | Auf Anfrage / On request | 1.257 | 1.660 | 1.973 |

| IFX-C- 8 x 80 x 1 | 640 | 8 | 80 | 1 | Auf Anfrage / On request | 1.280 | 1.690 | 2.009 |

| IFX-C- 8 x 63 x 1 | 504 | 8 | 63 | 1 | Auf Anfrage / On request | 1.030 | 1.361 | 1.618 |

| IFX-C- 8 x 50 x 1 | 400 | 8 | 50 | 1 | Auf Anfrage / On request | 897 | 1.185 | 1.408 |

| IFX-C- 8 x 40 x 1 | 320 | 8 | 40 | 1 | Auf Anfrage / On request | 744 | 983 | 1.168 |

| IFX-C- 8 x 32 x 1 | 256 | 8 | 32 | 1 | Auf Anfrage / On request | 627 | 829 | 985 |

| IFX-C- 8 x 24 x 1 | 192 | 8 | 24 | 1 | Auf Anfrage / On request | 530 | 700 | 832 |

| IFX-C- 8 x 100 x 1 | 800 | 8 | 100 | 1 | Auf Anfrage / On request | 1.461 | 1.930 | 2.294 |

| IFX-C- 9 x 9 x 0,8 | 64,8 | 9 | 9 | 0,8 | 🟡+🟢, 🔵, ⚫️ | 231 | 305 | 362 |

| IFX-C- 10 x 80 x 1 | 800 | 10 | 80 | 1 | Auf Anfrage / On request | 1.416 | 1.870 | 2.223 |

| IFX-C- 10 x 63 x 1 | 630 | 10 | 63 | 1 | Auf Anfrage / On request | 1.188 | 1.569 | 1.865 |

| IFX-C- 10 x 50 x 1 | 500 | 10 | 50 | 1 | ⚫️ | 1.027 | 1.357 | 1.613 |

| IFX-C- 10 x 40 x 1 | 400 | 10 | 40 | 1 | ⚫️ | 856 | 1.131 | 1.344 |

| IFX-C- 10 x 32 x 1 | 320 | 10 | 32 | 1 | ⚫️ | 726 | 959 | 1.140 |

| IFX-C- 10 x 24 x 1 | 240 | 10 | 24 | 1 | ⚫️ | 606 | 800 | 951 |

| IFX-C- 10 x 20 x 1 | 200 | 10 | 20 | 1 | Auf Anfrage / On request | 500 | 661 | 785 |

| IFX-C- 10 x 15,5 x 0,8 | 124 | 10 | 15,5 | 0,8 | 🟡+🟢, 🔵, ⚫️ | 348 | 460 | 546 |

| IFX-C- 10 x 100 x 1 | 1000 | 10 | 100 | 1 | Auf Anfrage / On request | 1.631 | 2.154 | 2.561 |

| IFX-C- 11 x 21 x 1 | 231 | 11 | 21 | 1 | 🟡+🟢, 🔵, ⚫️ | 567 | 749 | 890 |

| IFX-C- 12 x 100 x 1 | 1200 | 12 | 100 | 1 | Auf Anfrage / On request | 1.724 | 2.276 | 2.706 |

| Farbe Isolierung / color insulation |

*Current load values: Ambient temperature 35 °C, alternating current AC

**Insulation color on request!

| Typenbez. / Type | Querschnitt / Cross section [mm²] | Anzahl Lamellen / Number lamellas | Breite Lamellen / Width lamellas [mm] | Dicke Lamellen / Thickness lamellas [mm] | Farbe Isolierung / color insulation | Strombelastung/ Current rating [A]* 65°C | Strombelastung / Current rating [A]* 85°C | Strombelastung / Current rating [A]* 105°C |

|---|---|---|---|---|---|---|---|---|

| IFX-C- 2 x 32 x 1 | 64 | 2 | 32 | 1 | ⚫️ | 290 | 384 | 456 |

| IFX-C- 2 x 24 x 1 | 48 | 2 | 24 | 1 | ⚫️ | 242 | 320 | 380 |

| IFX-C- 2 x 20 x 1 | 40 | 2 | 20 | 1 | ⚫️ | 208 | 275 | 326 |

| IFX-C- 3 x 9 x 0,8 | 21 | 3 | 9 | 0,8 | ⚫️ | 121 | 160 | 190 |

| IFX-C- 3 x 32 x 1 | 96 | 3 | 32 | 1 | ⚫️ | 361 | 477 | 567 |

| IFX-C- 3 x 24 x 1 | 72 | 3 | 24 | 1 | ⚫️ | 303 | 400 | 475 |

| IFX-C- 3 x 20 x 1 | 60 | 3 | 20 | 1 | ⚫️ | 261 | 345 | 410 |

| IFX-C- 4 x 32 x 1 | 128 | 4 | 32 | 1 | ⚫️ | 421 | 556 | 661 |

| IFX-C- 4 x 24 x 1 | 96 | 4 | 24 | 1 | ⚫️ | 348 | 460 | 546 |

| IFX-C- 4 x 20 x 1 | 80 | 4 | 20 | 1 | ⚫️ | 303 | 400 | 475 |

| IFX-C- 4 x 16 x 0,8 | 49 | 4 | 16 | 0,8 | ⚫️ | 227 | 300 | 356 |

| IFX-C- 5 x 80 x 1 | 400 | 5 | 80 | 1 | ⚫️ | 1.022 | 1.350 | 1.605 |

| IFX-C- 5 x 63 x 1 | 315 | 5 | 63 | 1 | ⚫️ | 832 | 1.099 | 1.306 |

| IFX-C- 5 x 50 x 1 | 250 | 5 | 50 | 1 | ⚫️ | 702 | 927 | 1.102 |

| IFX-C- 5 x 40 x 1 | 200 | 5 | 40 | 1 | ⚫️ | 577 | 762 | 906 |

| IFX-C- 5 x 32 x 1 | 160 | 5 | 32 | 1 | ⚫️ | 480 | 634 | 753 |

| IFX-C- 5 x 24 x 1 | 120 | 5 | 24 | 1 | ⚫️ | 405 | 535 | 636 |

| IFX-C- 5 x 20 x 1 | 100 | 5 | 20 | 1 | ⚫️ | 321 | 424 | 504 |

| IFX-C- 5 x 100 x 1 | 500 | 5 | 100 | 1 | ⚫️ | 1.215 | 1.604 | 1.907 |

| IFX-C- 6 x 9 x 0,8 | 43 | 6 | 9 | 0,8 | ⚫️ | 189 | 250 | 297 |

| IFX-C- 6 x 80 x 1 | 480 | 6 | 80 | 1 | ⚫️ | 1.105 | 1.460 | 1.735 |

| IFX-C- 6 x 63 x 1 | 378 | 6 | 63 | 1 | ⚫️ | 949 | 1.253 | 1.489 |

| IFX-C- 6 x 50 x 1 | 300 | 6 | 50 | 1 | ⚫️ | 772 | 1.020 | 1.212 |

| IFX-C- 6 x 40 x 1 | 240 | 6 | 40 | 1 | ⚫️ | 632 | 835 | 992 |

| IFX-C- 6 x 32 x 1 | 192 | 6 | 32 | 1 | ⚫️ | 530 | 700 | 832 |

| IFX-C- 6 x 24 x 1 | 144 | 6 | 24 | 1 | ⚫️ | 439 | 580 | 689 |

| IFX-C- 6 x 20 x 1 | 120 | 6 | 20 | 1 | ⚫️ | 357 | 472 | 561 |

| IFX-C- 6 x 16 x 0,8 | 74 | 6 | 16 | 0,8 | ⚫️ | 287 | 380 | 451 |

| IFX-C- 6 x 100 x 1 | 600 | 6 | 100 | 1 | ⚫️ | 1.257 | 1.660 | 1.973 |

| IFX-C- 8 x 80 x 1 | 640 | 8 | 80 | 1 | ⚫️ | 1.280 | 1.690 | 2.009 |

| IFX-C- 8 x 63 x 1 | 504 | 8 | 63 | 1 | ⚫️ | 1.030 | 1.361 | 1.618 |

| IFX-C- 8 x 50 x 1 | 400 | 8 | 50 | 1 | ⚫️ | 897 | 1.185 | 1.408 |

| IFX-C- 8 x 40 x 1 | 320 | 8 | 40 | 1 | ⚫️ | 744 | 983 | 1.168 |

| IFX-C- 8 x 32 x 1 | 256 | 8 | 32 | 1 | ⚫️ | 627 | 829 | 985 |

| IFX-C- 8 x 24 x 1 | 192 | 8 | 24 | 1 | ⚫️ | 530 | 700 | 832 |

| IFX-C- 8 x 100 x 1 | 800 | 8 | 100 | 1 | ⚫️ | 1.461 | 1.930 | 2.294 |

| IFX-C- 10 x 80 x 1 | 800 | 10 | 80 | 1 | ⚫️ | 1.416 | 1.870 | 2.223 |

| IFX-C- 10 x 63 x 1 | 630 | 10 | 63 | 1 | ⚫️ | 1.188 | 1.569 | 1.865 |

| IFX-C- 10 x 50 x 1 | 500 | 10 | 50 | 1 | ⚫️ | 1.027 | 1.357 | 1.613 |

| IFX-C- 10 x 40 x 1 | 400 | 10 | 40 | 1 | ⚫️ | 856 | 1.131 | 1.344 |

| IFX-C- 10 x 32 x 1 | 320 | 10 | 32 | 1 | ⚫️ | 726 | 959 | 1.140 |

| IFX-C- 10 x 24 x 1 | 240 | 10 | 24 | 1 | ⚫️ | 606 | 800 | 951 |

| IFX-C- 10 x 20 x 1 | 200 | 10 | 20 | 1 | ⚫️ | 500 | 661 | 785 |

| IFX-C- 10 x 16 x 0,8 | 124 | 10 | 16 | 0,8 | ⚫️ | 348 | 460 | 546 |

| IFX-C- 10 x 100 x 1 | 1.000 | 10 | 100 | 1 | ⚫️ | 1.631 | 2.154 | 2.561 |

| IFX-C- 11 x 21 x 1 | 231 | 11 | 21 | 1 | ⚫️ | 567 | 749 | 890 |

| IFX-C- 12 x 100 x 1 | 1.200 | 12 | 100 | 1 | ⚫️ | 1.724 | 2.276 | 2.706 |

| Farbe Isolierung / color insulation |

*Current load values: Ambient temperature 35 °C, alternating current AC

**Insulation color on request!

| Typenbez. / Type | Querschnitt / Cross section [mm²] | Anzahl Lamellen / Number lamellas | Breite Lamellen / Width lamellas [mm] | Dicke Lamellen / Thickness lamellas [mm] | Farbe Isolierung / color insulation [Cu-ETP blank/ bare] | Farbe Isolierung / color insulation [Cu-ETP verzinnt/ tinned] | Strombelastung/ Current rating [A]* 65°C | Strombelastung/ Current rating [A]* 85°C | Strombelastung/ Current rating [A]* 105°C |

|---|---|---|---|---|---|---|---|---|---|

| IFX-P- 5 x 50 x 1 | 250 | 5 | 50 | 1 | Auf Anfrage / On request | Auf Anfrage / On request | 702 | 927 | 1.102 |

| IFX-P- 5 x 40 x 1 | 200 | 5 | 40 | 1 | Auf Anfrage / On request | Auf Anfrage / On request | 577 | 762 | 906 |

| IFX-P- 5 x 32 x 1 | 160 | 5 | 32 | 1 | Auf Anfrage / On request | Auf Anfrage / On request | 480 | 634 | 753 |

| IFX-P- 5 x 24 x 1 | 120 | 5 | 24 | 1 | Auf Anfrage / On request | Auf Anfrage / On request | 405 | 535 | 636 |

| IFX-P- 5 x 20 x 1 | 100 | 5 | 20 | 1 | Auf Anfrage / On request | Auf Anfrage / On request | 321 | 424 | 504 |

| IFX-P- 5 x 100 x 1 | 500 | 5 | 100 | 1 | Auf Anfrage / On request | Auf Anfrage / On request | 1.215 | 1.604 | 1.907 |

| IFX-P- 12 x 100 x 1 | 1.200 | 12 | 100 | 1 | Auf Anfrage / On request | Auf Anfrage / On request | 1.724 | 2.276 | 2.706 |

| IFX-P- 10 x 80 x 1 | 800 | 10 | 80 | 1 | Auf Anfrage / On request | Auf Anfrage / On request | 1.280 | 1.690 | 2.009 |

| IFX-P- 10 x 63 x 1 | 630 | 10 | 63 | 1 | Auf Anfrage / On request | Auf Anfrage / On request | 1.030 | 1.361 | 1.618 |

| IFX-P- 10 x 50 x 1 | 500 | 10 | 50 | 1 | Auf Anfrage / On request | Auf Anfrage / On request | 897 | 1.185 | 1.408 |

| IFX-P- 10 x 40 x 1 | 400 | 10 | 40 | 1 | Auf Anfrage / On request | Auf Anfrage / On request | 856 | 1.131 | 1.344 |

| IFX-P- 10 x 32 x 1 | 320 | 10 | 32 | 1 | Auf Anfrage / On request | Auf Anfrage / On request | 726 | 959 | 1.140 |

| IFX-P- 10 x 24 x 1 | 240 | 10 | 24 | 1 | Auf Anfrage / On request | Auf Anfrage / On request | 606 | 800 | 951 |

| IFX-P- 10 x 20 x 1 | 200 | 10 | 20 | 1 | Auf Anfrage / On request | Auf Anfrage / On request | 500 | 661 | 785 |

| IFX-P- 10 x 120 x 1 | 1.200 | 10 | 120 | 1 | Auf Anfrage / On request | Auf Anfrage / On request | 1.780 | 2.350 | 2.794 |

| IFX-P- 10 x 100 x 1 | 1.000 | 10 | 100 | 1 | Auf Anfrage / On request | Auf Anfrage / On request | 1.631 | 2.154 | 2.561 |

| Farbe Isolierung / color insulation [Cu-ETP blank/ bare] | Farbe Isolierung / color insulation [Cu-ETP verzinnt/ tinned] |

*Current load values: Ambient temperature 35 °C, alternating current AC

** Cu-ETP bare & tinned Color of insulation grey on request!

| Typenbez. / Type | Querschnitt / Cross section [mm²] | Anzahl Lamellen / Number lamellas | Breite Lamellen / Width lamellas [mm] | Dicke Lamellen / Thickness lamellas [mm] | Farbe Isolierung / color insulation [Cu-ETP blank/ bare] | Farbe Isolierung / color insulation [Cu-ETP verzinnt/ tinned] | Strombelastung/ Current rating [A]* 65°C | Strombelastung / Current rating [A]* 85°C | Strombelastung / Current rating [A]* 105°C |

|---|---|---|---|---|---|---|---|---|---|

| IFX-R- 5 x 20 x 1 | 100 | 5 | 20 | 1 | Auf Anfrage / On request | ⚫️ | 321 | 424 | 504 |

| IFX-R- 5 x 24 x 1 | 120 | 5 | 24 | 1 | Auf Anfrage / On request | ⚫️ | 405 | 535 | 636 |

| IFX-R- 5 x 32 x 1 | 160 | 5 | 32 | 1 | Auf Anfrage / On request | ⚫️ | 480 | 634 | 753 |

| IFX-R- 10 x 24 x 1 | 240 | 10 | 24 | 1 | Auf Anfrage / On request | ⚫️ | 606 | 800 | 951 |

| IFX-R- 10 x 32 x 1 | 320 | 10 | 32 | 1 | Auf Anfrage / On request | ⚫️ | 726 | 959 | 1.140 |

| IFX-R- 10 x 40 x 1 | 400 | 10 | 40 | 1 | Auf Anfrage / On request | ⚫️ | 856 | 1.131 | 1.344 |

| IFX-R- 10 x 50 x 1 | 500 | 10 | 50 | 1 | Auf Anfrage / On request | ⚫️ | 1.027 | 1.357 | 1.613 |

| IFX-R- 6 x 16 x 0,8 | 74,4 | 6 | 16 | 0,8 | Auf Anfrage / On request | ⚫️ | 287 | 380 | 451 |

| IFX-R- 6 x 15,5 x 0,8 (verzinnt) | 74,4 | 6 | 15,5 | 0,8 | Auf Anfrage / On request | ⚫️ | 287 | 380 | 451 |

| IFX-R- 6 x 9 x 0,8 | 43,2 | 6 | 9 | 0,8 | Auf Anfrage / On request | ⚫️ | 189 | 250 | 297 |

| IFX-R- 10 x 16 x 0,8 | 124 | 10 | 16 | 0,8 | Auf Anfrage / On request | ⚫️ | 348 | 460 | 546 |

| Farbe Isolierung / color insulation [Cu-ETP blank/ bare] | Farbe Isolierung / color insulation [Cu-ETP verzinnt/ tinned] |

*Current load values: Ambient temperature 35 °C, alternating current AC

** Cu-ETP blank Color of insulation black on request!

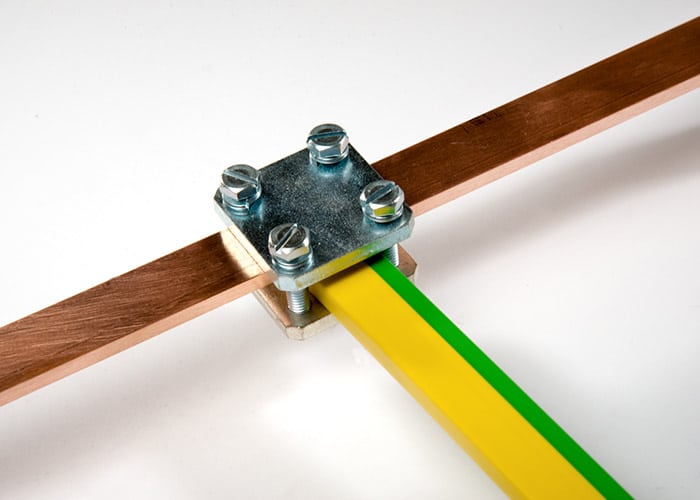

Assembly instructions Isoflexx®

The following standards should be considered for bolting Isoflexx® busbars:

- DIN 43671 & 43670 Busbars with rectangular cross-section.

- DIN 43673 Currents for busbars – drilling and screwing

Isoflexx® connections can be easily made by yourself with the right tools & accessories. By stripping the ends, Isoflexx® offers more safety in your installations, because you do not need cable lugs. The connections must be stripped by yourself.

Treatment of the contact surfaces

The surfaces should be even, but not polished. The contact resistance is lower if the contact surfaces have a medium roughness (RA 1.6-3.2). Contact surfaces should be free of oxide and grease. If this is not the case, the contact surfaces must be cleaned.

Possible SPS assembly

- Cutting to length, bending, twisting

- Insertion of hole patterns

- Press welding or tacking connections

- Personalisations

- Packaging according to customer specification