Area of application for Earth Braids

In modern switchgear with, for example, programmable logic controllers or fieldbus connections, high-frequency earthing is extremely important. Not only the ohmic direct current resistance plays a major role here, but also the impedance, which increases with frequency. The conductor shape, the total length and the connection technology are decisive factors here.

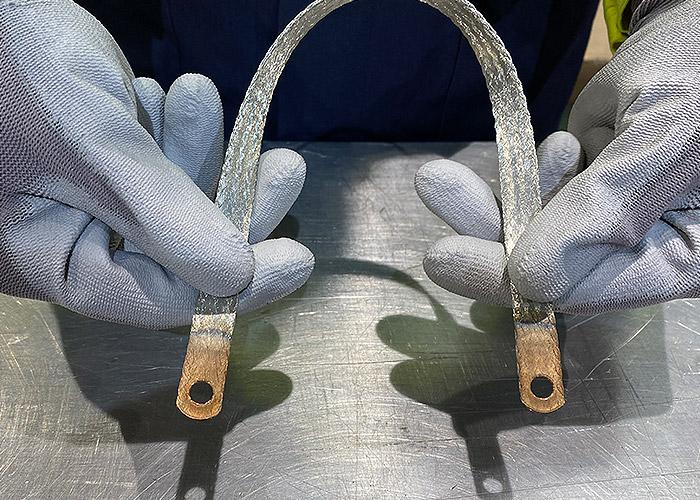

Earth Braids have a lower impedance than comparable round grounding cables and are therefore much better suited for high-frequency grounding. In addition, they offer ideal low contact resistance, which can only be achieved by welding.

SPS Earth Braids are also extremely well suited for ensuring the electromagnetic compatibility of different system components and devices.

- Extremely high flexibility

- Low heating in the event of a short circuit

- Best long-term mechanical behaviour

- High operational reliability

- Excellent contact transition

Certifications SPS Earth Braids

Conductor Material SPS Earth Braids

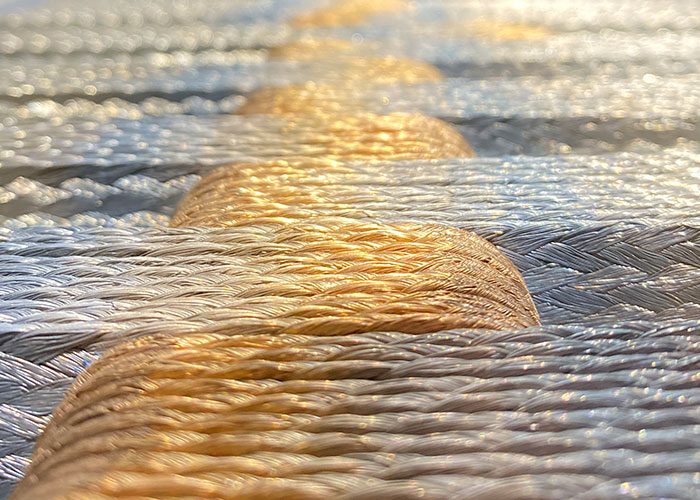

- Highly flexible flat braids made of tinned Cu-ETP1

- Electrical conductance 58 MS/m

- Single wire thickness 0.15 mm for a maximum of flexibility

- Cu-ETP1 tinned (corrosion-resistant)

- Cross-sections from 6 to 50 mm²

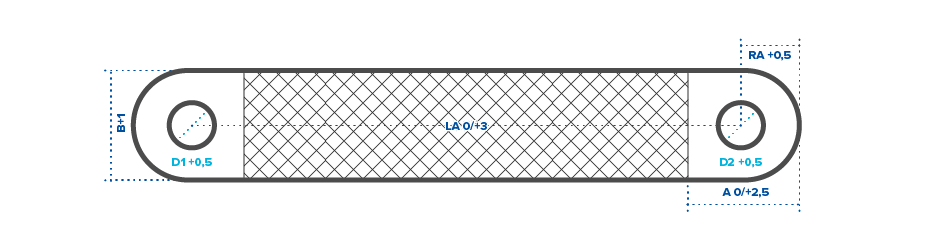

- Length is defined as the hole center distance

- Lengths from 100 to 500 mm, in 50 mm steps

By welding the connections, minimal contact resistance is achieved. This eliminates the need for additional contact sleeves with increased resistances.

- The welding guarantees constant resistances. There is no aging due to corrosion, as is the case with the use of contact sleeves.

- The welded connections can withstand exceptionally high short-circuit currents with high limit temperatures.

- In contrast to soldered connections, the connections cannot be softened.

Properties of Earth Braids

Technical details

MBS earth braids Type description*:

MBS [cross-section mm²] –

[LA = hole spacing length] –

[D1 / D2 = hole diameter]

| Typenbez. / Type* | Querschnitt [mm²] / Cross section | LA Lochabstand/ Hole distance [mm]** | B Breite / Width [mm] (± 1) | RA Abstand / Distance [mm] | A Anschlusslänge / Length connection [mm] | D1/D2 Durchmesser / Diameter [mm]*** | Gewicht / Weight [kg/m] |

|---|---|---|---|---|---|---|---|

| MBS 6-LA-D1/D2 | 6 | 100-500 | 10 | 7,5 | 16 | [4,5/4,5] [4,5/5,5] [4,5/6,5] [5,0/5,0] [5,5/6,5] [6,5/6,5] | 0,062 |

| MBS 10-LA-D1/D2 | 10 | 100-500 | 12 | 7,5 | 16 | [4,5/4,5] [4,5/5,5] [4,5/6,5] [5,0/5,0] [5,5/6,5] [5,5/8,5] [6,5/6,5] [6,5/8,5] [8,5/8,5] | 0,104 |

| MBS 16-LA-D1/D2 | 16 | 100-500 | 15 | 7,5 | 16 | [4,5/4,5] [4,5/5,5] [4,5/6,5] [5,0/5,0] [5,5/6,5] [5,5/8,5] [6,5/6,5] [6,5/8,5] [8,5/8,5] | 0,164 |

| MBS 25-LA-D1/D2 | 25 | 100-500 | 23 | 11,5 | 21 | [5,5/6,5] [6,5/6,5] [6,5/8,5] [6,5/10,5] [8,5/8,5] [8,5/10,5] [8,5/12,5] [10,5/10,5] [10,5/12,5] [12,5/12,5] | 0,262 |

| MBS 35-LA-D1/D2 | 35 | 100-500 | 23 | 14 | 22 (26) | [5,5/6,5] [6,5/6,5] [6,5/8,5] [6,5/10,5] [8,5/8,5] [8,5/10,5] [8,5/12,5] [10,5/10,5] [10,5/12,5] [12,5/12,5] | 0,366 |

| MBS 50-LA-D1/D2 | 50 | 100-500 | 28 | 14 | 22 (26) | [6,5/8,5] [8,5/8,5] [8,5/10,5] [8,5/12,5] [10,5/10,5] [10,5/12,5] [12,5/12,5] | 0,528 |

| MBS 70-LA-D1/D2 | 70 | 100-500 | 30 | 14 | 22 (26) | [6,5/8,5] [8,5/8,5] [8,5/10,5] [8,5/12,5] [10,5/10,5] [10,5/12,5] [12,5/12,5] | 0,733 |

** Lengths in 50 mm increments. The length is defined as hole center distance.

*** Individual diameters on request!

Possible SPS assembly

- Custom lengths available on request

- Customised insulation available on request

- Personalisations

- Packaging according to customer specifications